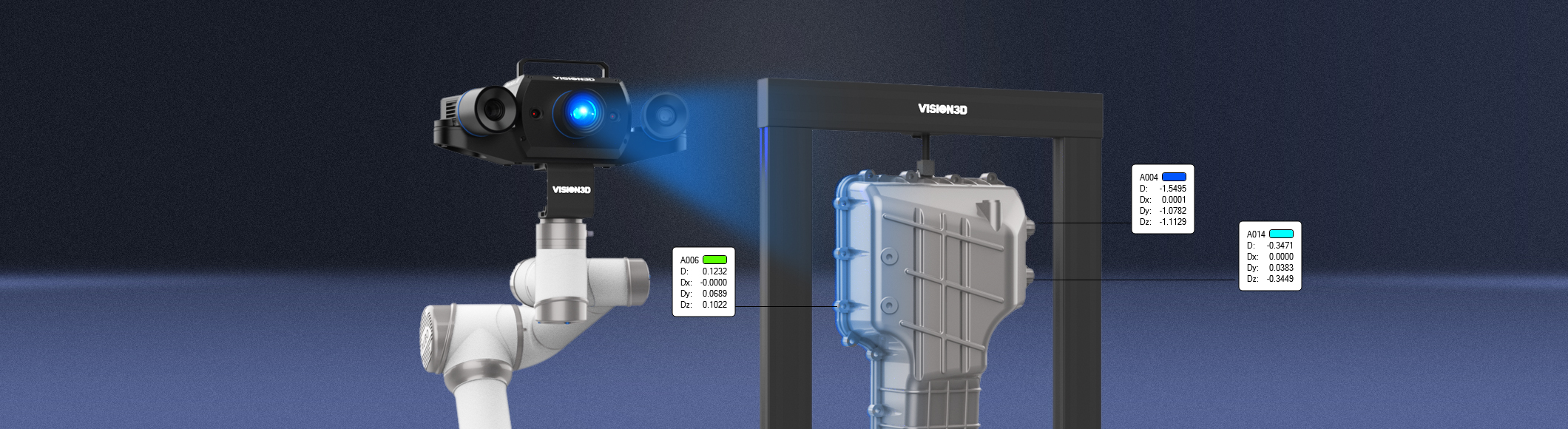

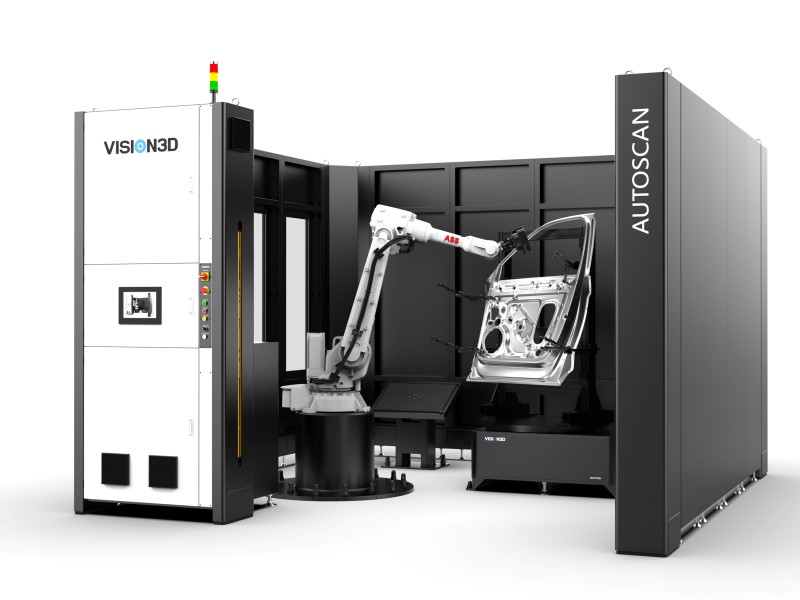

The AutoScan Automated Measurement System features a modular architecture that provides high-precision, full-dimensional inspection solutions for intelligent manufacturing. Supporting automated inspection for workpieces from under 5,000 mm to full-vehicle scale, the system integrates VisionInspect measurement software and leverages a parallel computing architecture for efficient data processing.

The innovative markerless alignment algorithm enables full-dimensional measurement without the need for physical reference targets, simplifying fixture design and enhancing overall inspection efficiency. Widely applied in automotive and aerospace sectors, the system meets the rigorous quality control requirements for complex workpieces.

Engineered for precision components with dimensions up to 500 mm.

Tailored for medium - sized parts with dimensions up to 1,000 mm.

Designed for medium-to-large workpieces with dimensions up to 2,000 mm.

Optimized for large-scale and highly complex structural components up to 5,000 mm.

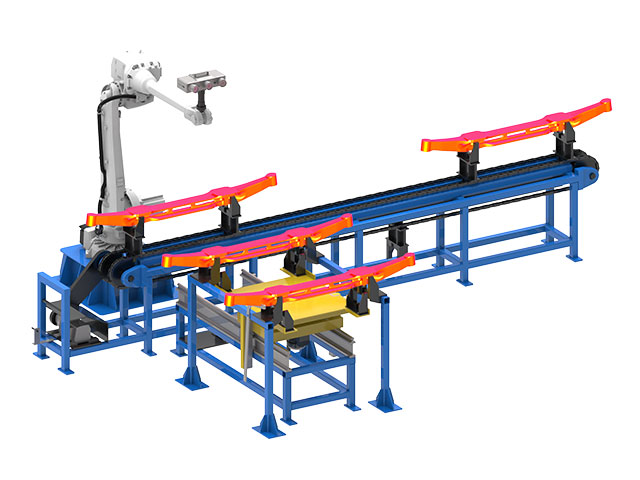

Mobile Automated 3D Measurement Station

Dedicated to in-line measurement of hot forgings at extreme temperatures up to 1,100 °C.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.more details