Automated In-line Measurement During Additive Manufacturing

Additive Manufacturing (AM) is an advanced manufacturing technology driven by 3D digital data that builds components layer-by-layer based on the principle of discrete-stacking. Compared to traditional subtractive or formative manufacturing methods—which involve material removal, cutting, assembly, and machining—AM simplifies the production of components with intricate geometries. It is characterized by short process cycles, high material utilization, the ability to form complex structures, and support for personalized design. Consequently, it is regarded as a transformative technology and is widely applied in aerospace, automotive manufacturing, mold making, and casting.

As an emerging technology, current inspection in AM mostly focuses on equipment monitoring, with insufficient data collection during the material formation process. Due to the complex thermophysical and non-equilibrium metallurgical processes in Laser Powder Bed Fusion (LPBF), the formation process is often accompanied by defects such as spatter, cracking, and poor surface quality, which limit the broader application of AM technology. Therefore, timely defect detection and the implementation of in-line measurement are critical for enhancing process stability and the forming quality of complex parts.

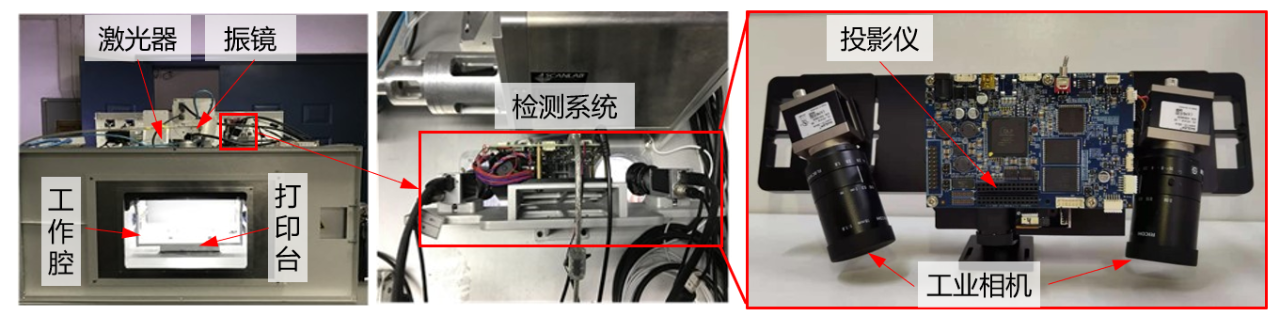

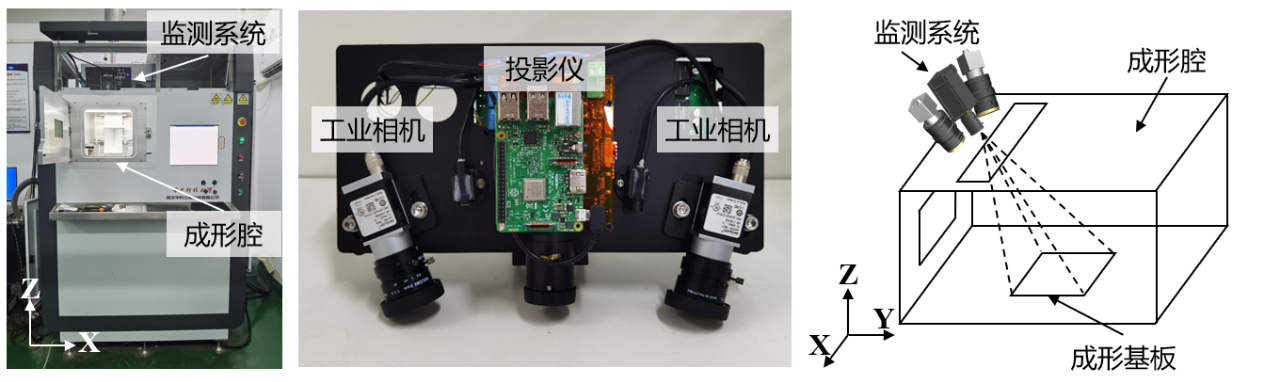

VISION3D’s independently developed industrial-grade 3D cameras feature multi-platform SDKs and robust system compatibility, allowing for seamless integration with SLS (Selective Laser Sintering) and SLM (Selective Laser Melting) equipment.

The system provides non-destructive in-line monitoring and visual inspection within the build chamber. It rapidly and accurately acquires the surface profile, 3D dimensions, flatness, and defect status of internal components. Meanwhile, measurement data is visualized in real-time and customized reports are generated to assist in subsequent process correction and optimization.