3D Dimensional Inspection of Mobile Phone Cover Glass

From raw material to finished product, mobile phone cover glass undergoes a series of processes including cutting, edging, vacuum forging, tempering, and silk-screen printing. Any defect in these stages can result in substandard quality. For instance, poor flatness often leads to touch feedback offset or uneven tactile surfaces. Deviations in the size and position of circular apertures can also compromise assembly and functionality. Therefore, 3D dimensional inspection has become an essential pre-assembly process for cover glass.

Inspection Scope

- Linear Dimensions: Length, width, height, and R-angle (fillet radius).

- Critical Features: Position and diameter of circular holes.

- GD&T: Flatness, position, etc.

- Profiles: Curved surface profiles and hole edge profiles.

Challenges of Traditional Methods

- Efficiency and Precision: Traditional tools like calipers and manual visual inspection are slow and lack precision, failing to meet the high-quality, high-efficiency demands of mass production.

- Deformation Risk: Some methods use tactile probes for contact measurement. The applied contact force can cause localized deformation, leading to measurement errors.

- Market Landscape: While foreign 3D vision systems previously dominated microscopic high-precision inspection due to early technical maturity, domestic brands are rapidly advancing toward specialization and refinement. Supported by national policies, domestic substitution is becoming the strategic trend in the machine vision industry.

3D Scanning Solution

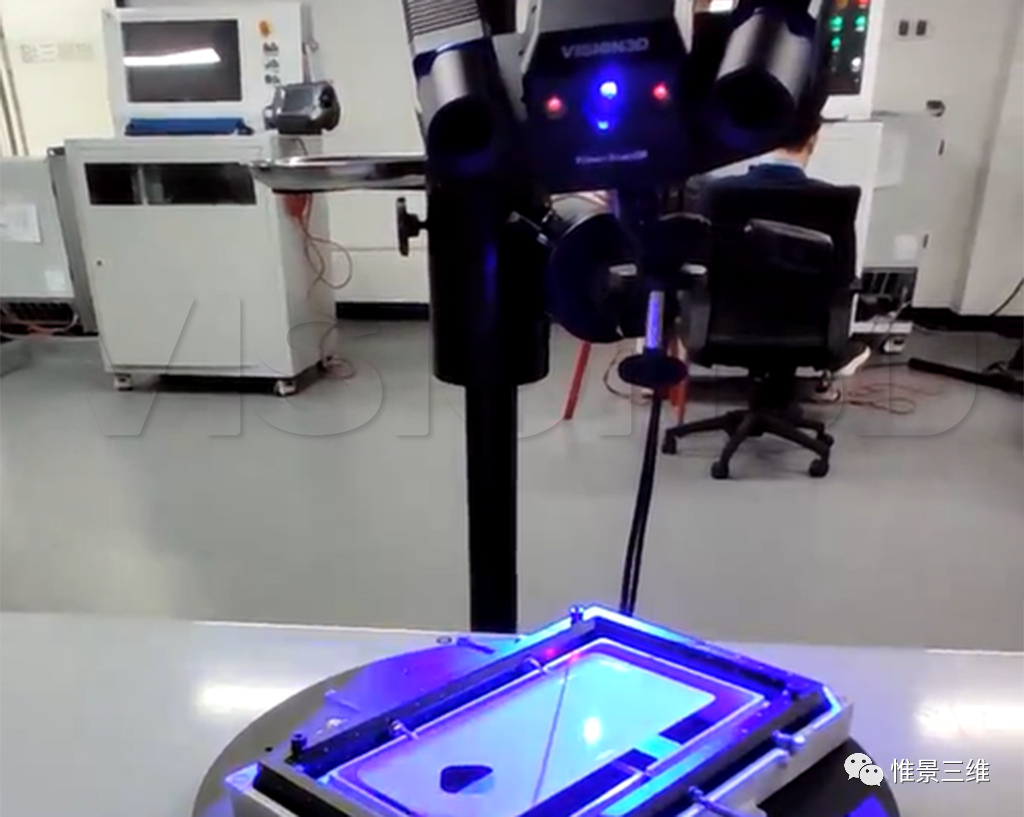

VISION3D utilizes the PowerScan Series Blue Light Area Scanning System. Equipped with high-performance 3D sensors, it rapidly captures surface details and acquires high-precision 3D dimensional data for small-to-medium-sized components.

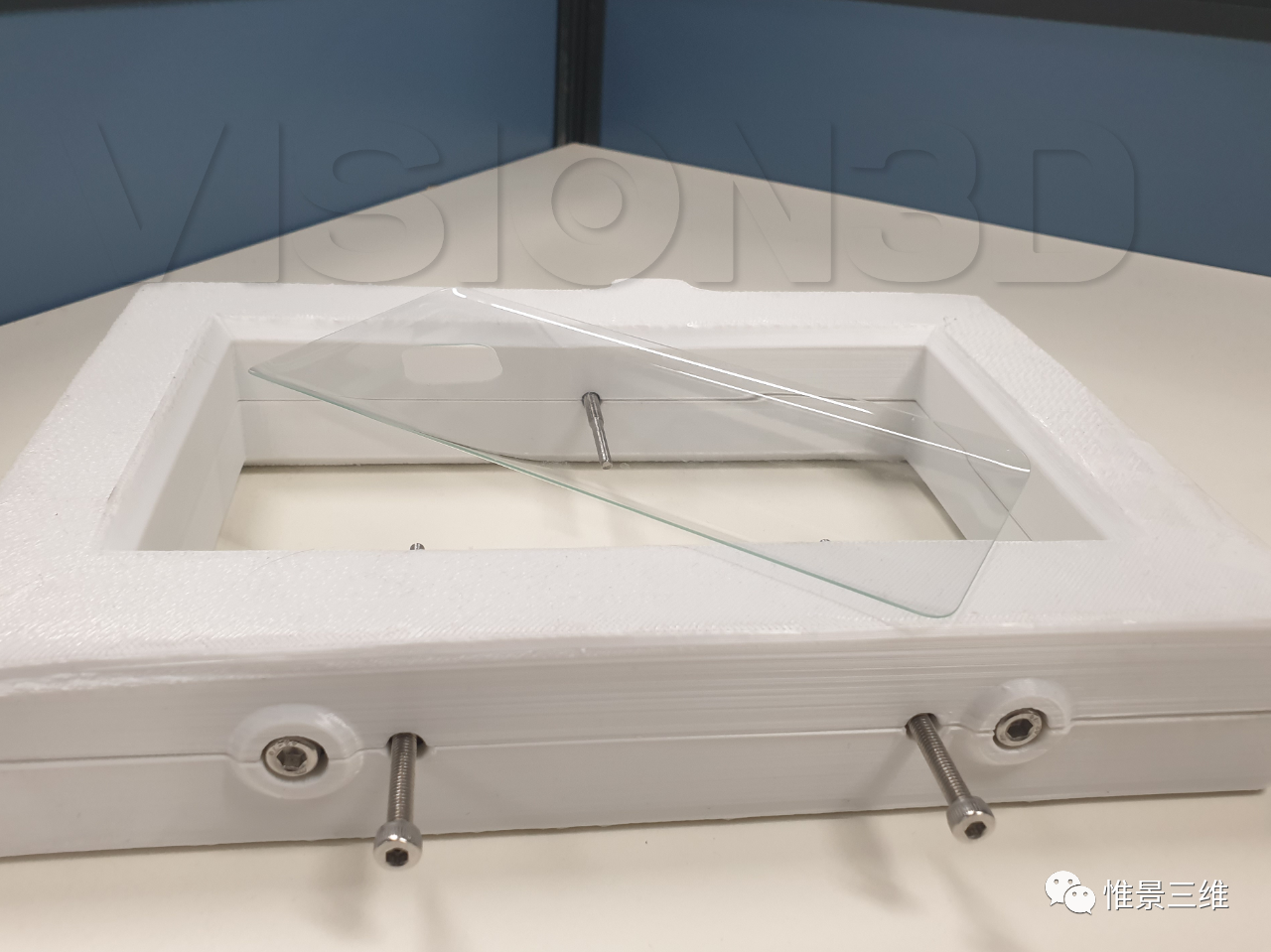

- Non-contact Measurement: The PowerScan series employs non-contact blue-light structured light technology. With zero contact force, it prevents surface damage to the glass while completing scans precisely. With a single-frame scan speed of ≤1 second, complete part data can be acquired within one minute, satisfying high-volume inspection requirements.Image | Non-contact Blue Light Structured Light Measurement

- Advanced Algorithms: Built-in optimized algorithms precisely analyze critical data such as length/width, flatness, and curved profile curvature. With a maximum accuracy of 0.008 mm, it faithfully reconstructs part details. Furthermore, algorithmic data thinning significantly reduces data volume, drastically improving processing and analysis speeds.Image | Inspection Point Cloud

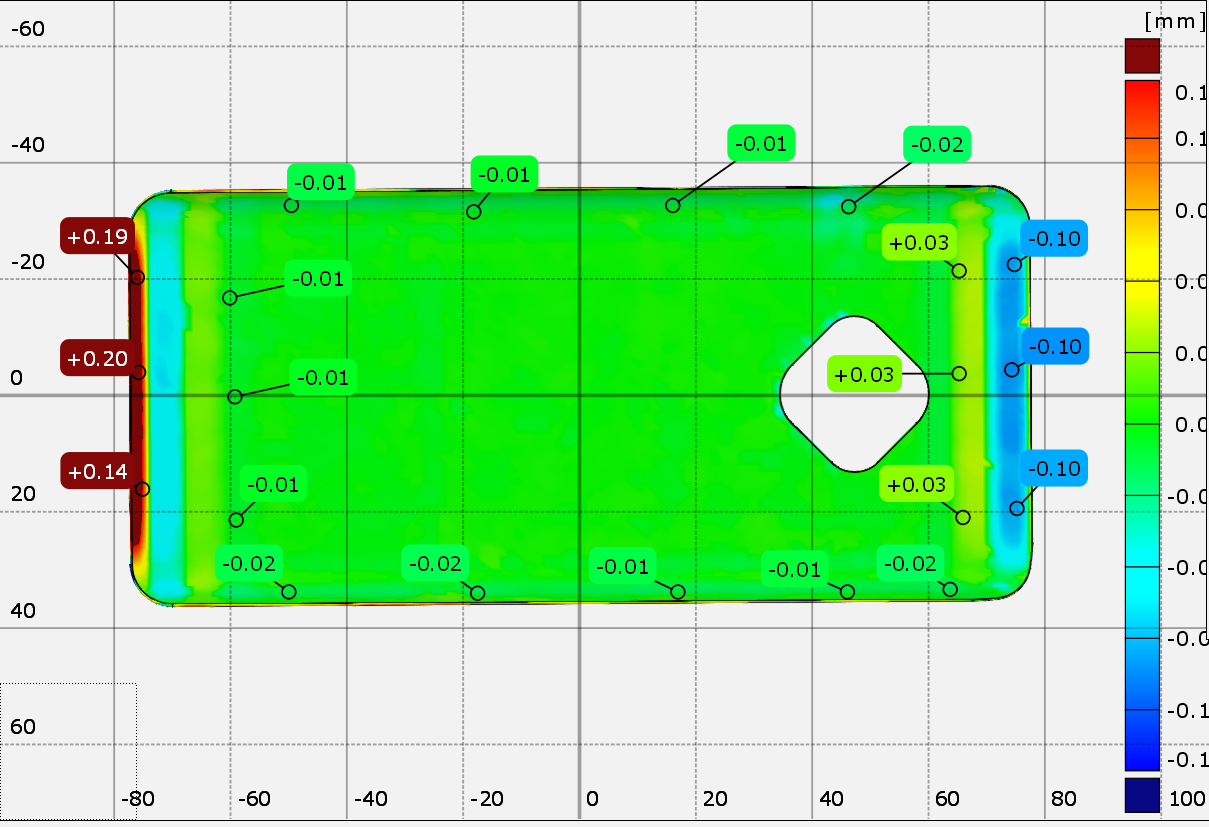

- Data-Driven Optimization: Utilizing data processing software, the system automatically compares scanned data against the original CAD model to generate customized inspection reports. Based on batch data, trend analysis of key points and features can be performed to facilitate manufacturing process optimization.Image | Inspection Report of Mobile Phone Cover Glass

Corporate Profile: As a leading domestic enterprise, Wuhan VISION3D Technology Co., Ltd. remains dedicated to the field of optical 3D measurement. Focused on the practical demands for 3D digital technology across various sectors, the company has independently developed multiple series of 3D measurement equipment, with long-term applications in aerospace, automotive manufacturing, rail transit, and education.