Automated 3D Inspection for Aero-Engine Impellers

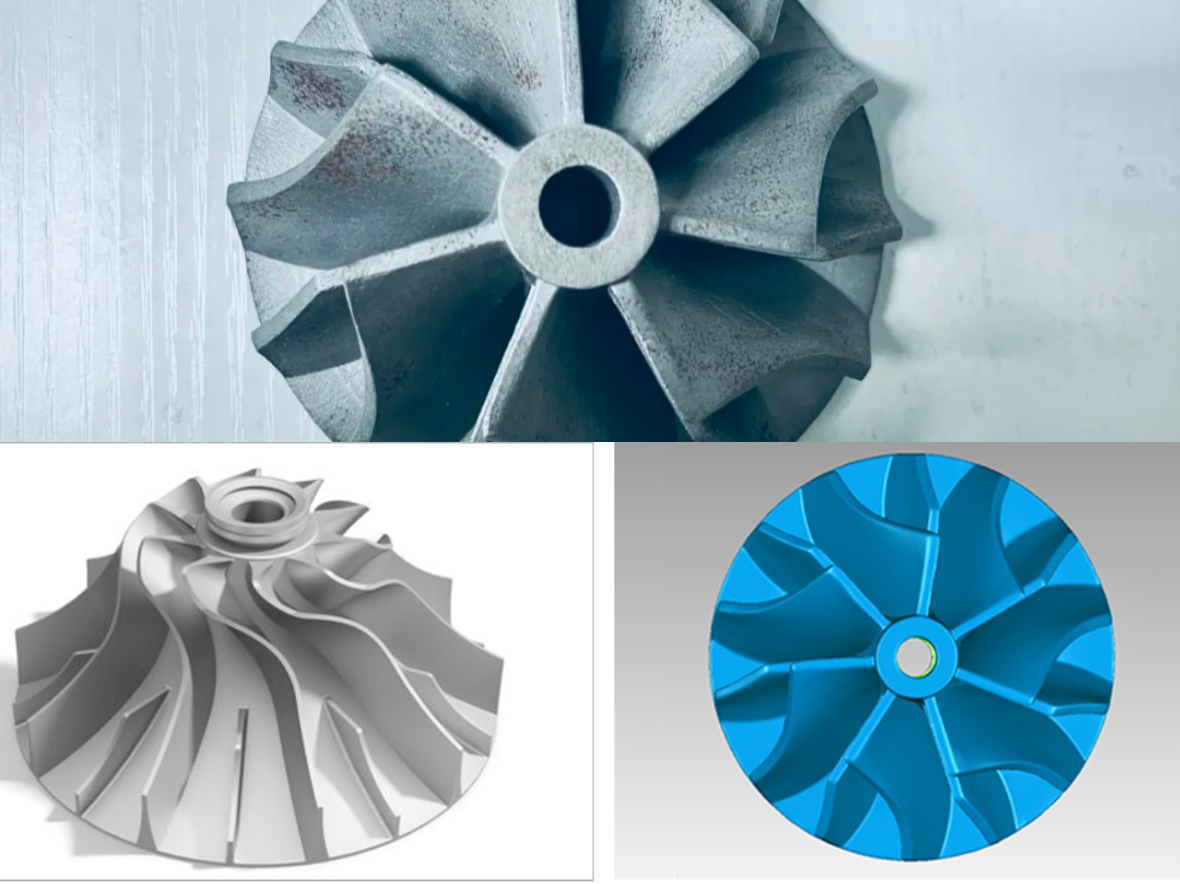

The aero-engine is globally recognized as one of the most technologically advanced and structurally complex industrial products. A single engine consists of tens of thousands of components, and its manufacturing precision directly impacts flight safety, necessitating stringent quality standards.

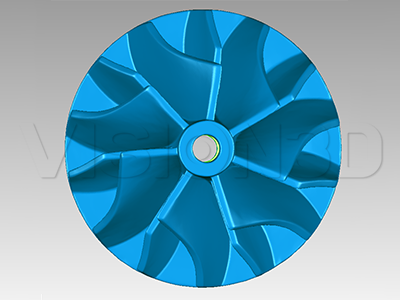

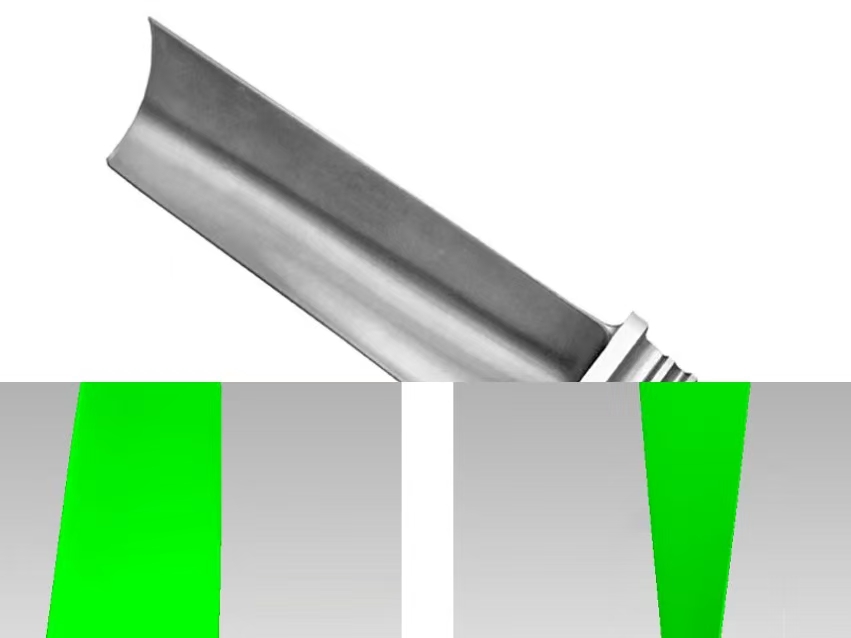

The impeller typically has a small form factor, with a diameter of approximately 10 cm. Its structure is composed of intricate curved surfaces and narrow, twisted 3D flow passages, which create numerous blind spots and shadowed areas. These factors, combined with the high volume of inspection points, make measurement extremely challenging. Traditional inspection methods struggle to meet the demands for high-quality, high-efficiency batch detection in modern production.

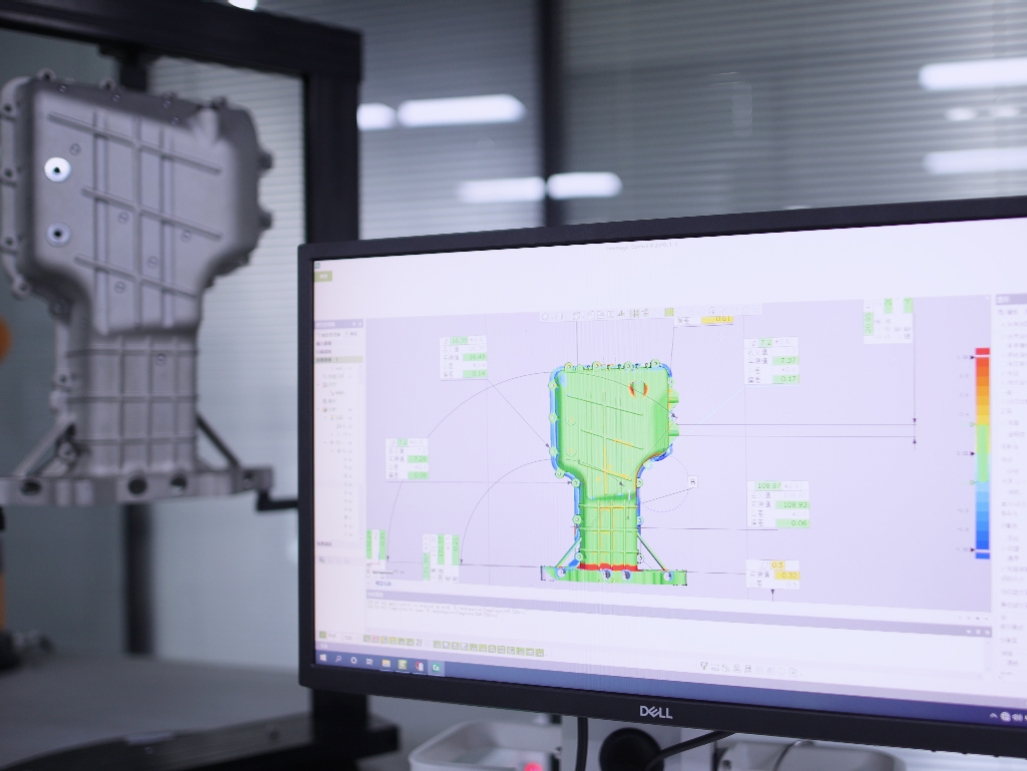

The AutoScan Series Automated 3D Measurement System by VISION3D utilizes structured-light (area scanning) and multi-view automatic registration technologies. It delivers high-precision, high-efficiency inspection capabilities and offers multiple alignment/positioning modes. The system enables rapid acquisition of 3D surface data and generates customized inspection reports without the need for targets (markers) or spraying (developer), facilitating seamless automated batch inspection of impellers.