Automated 3D Inspection for Complex Aircraft Castings

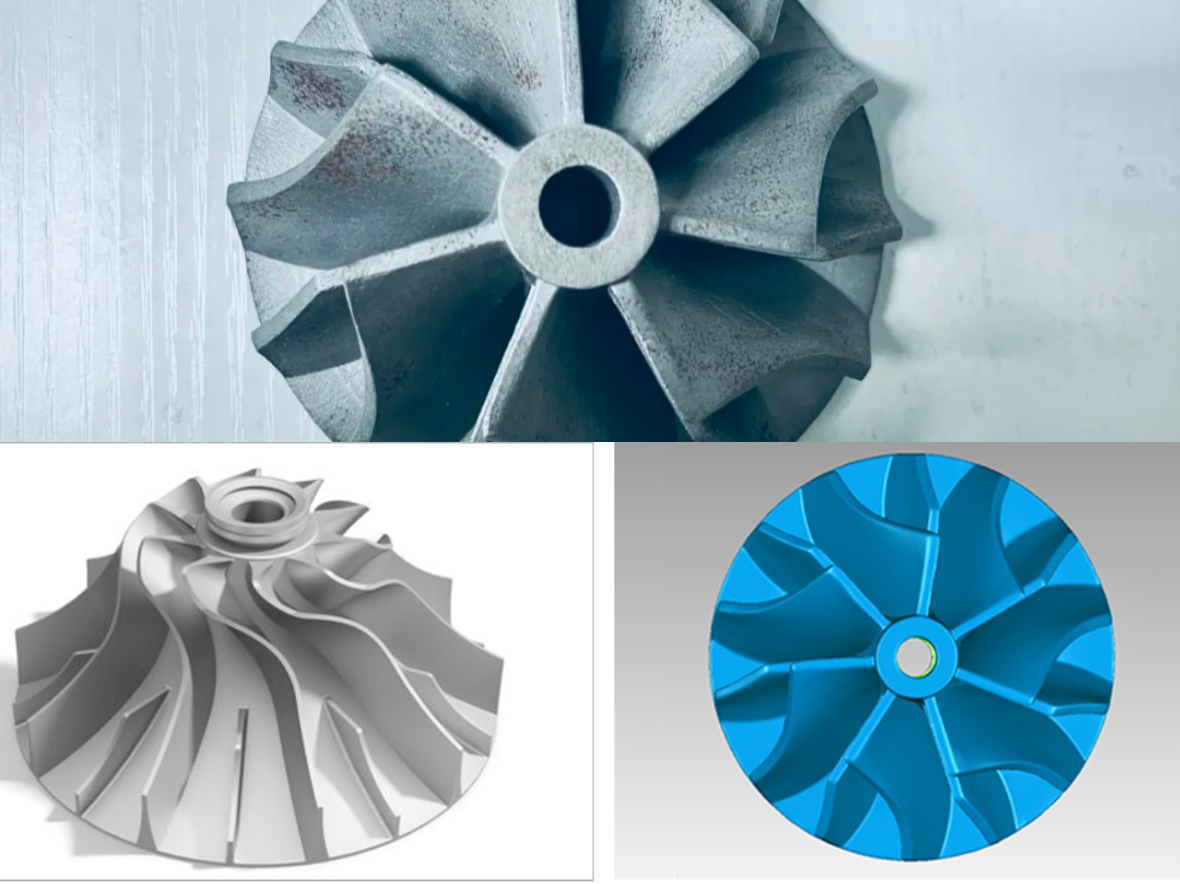

Castings are widely utilized across aerospace, automotive, marine, and engineering machinery sectors. For titanium alloy engine casings and airframe components, ensuring the precision of wax patterns and final castings is critical to enhancing manufacturing efficiency and guaranteeing product quality, given their large volumes and intricate geometries.

A key criterion for determining if a casting meets process requirements is whether its machining allowance is sufficient. For components such as aircraft casings, vertical stabilizer frames, missile compartments, and satellite shells, automated 3D measurement is employed prior to machining. This process rapidly acquires complete data and precisely inspects dimensions across all sections to verify if the machining allowance aligns with technical specifications.

Due to the limitations of traditional inspection, measuring large castings is often labor-intensive and time-consuming. 3D measurement technology, with its advantages in high precision, efficiency, and real-time feedback, significantly improves accuracy from blank inspection through to subsequent machining stages.

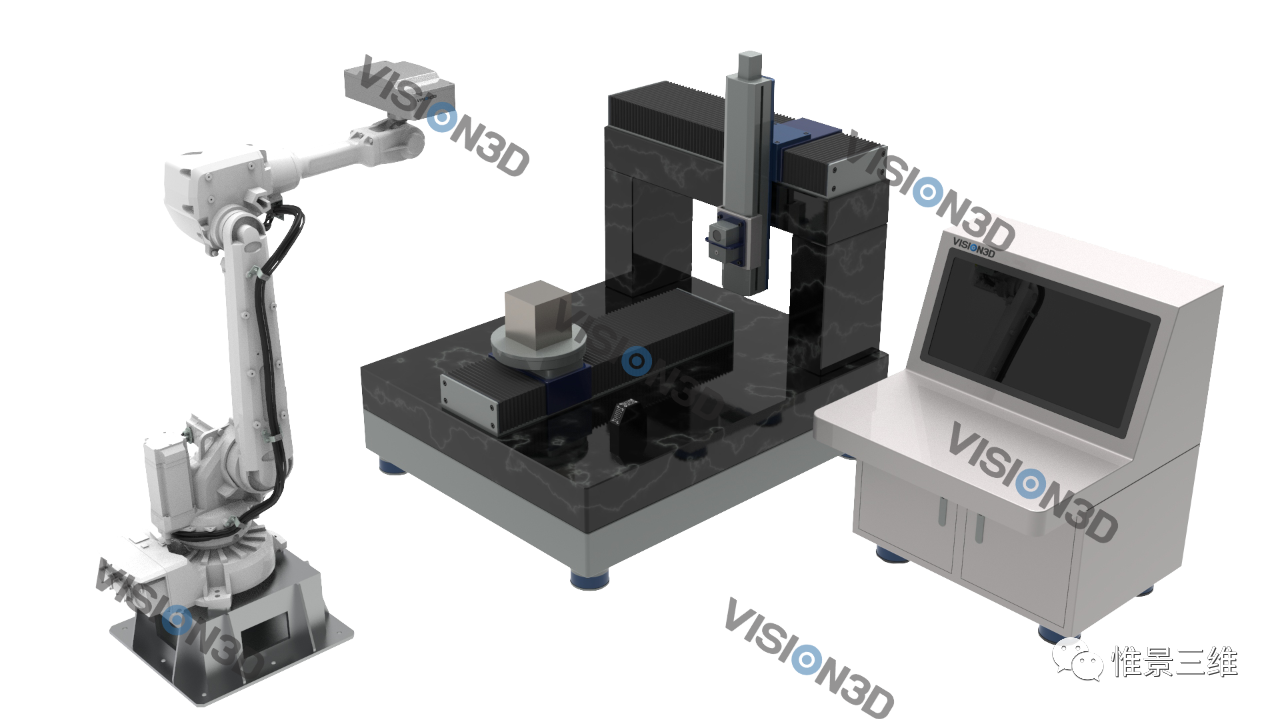

VISION3D Automated Inspection Solution

The AutoScan-D Automated 3D Measurement, Allowance Analysis, and Laser Scribing System by VISION3D enables rapid allowance measurement and precise datum positioning for complex castings. It further guides laser scribing equipment to mark machining reference lines, providing a direct interface for high-precision downstream machining.

Automated 3D Measurement

The system performs fully automated 3D scanning of castings without manual intervention to obtain comprehensive dimensional data and a complete 3D model. During the scan, measurement data is analyzed in real-time, and customized inspection reports are generated instantly. Image | At-line Automated 3D Inspection of Casting Blanks.

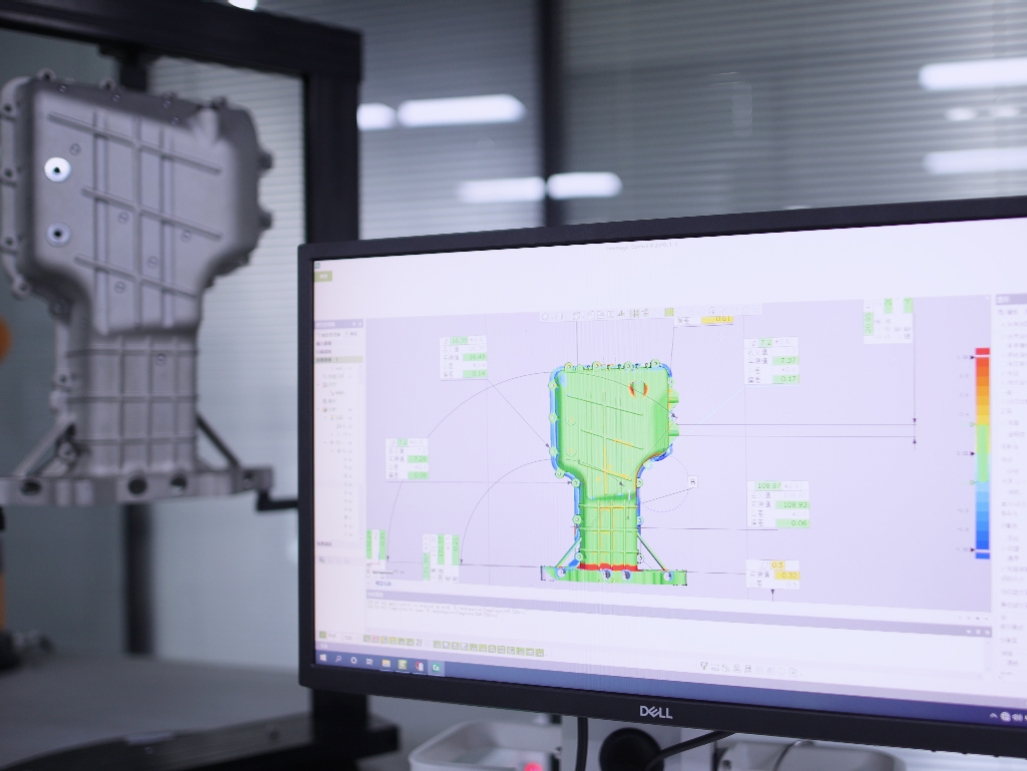

Machining Allowance Comparative Analysis

By comparing 3D scan data against the nominal CAD model, the system automatically analyzes the allowance of each machining surface. It verifies if the allowance meets subsequent process requirements and, once confirmed, identifies the optimal datum state (best-fit alignment). Image | Casting Allowance Analysis Results and Precision Extraction.

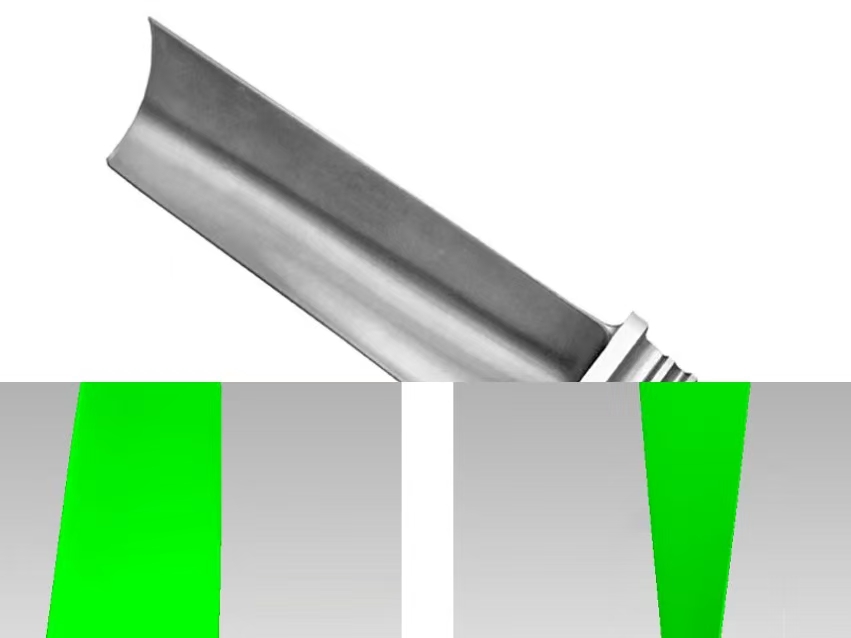

Automated Laser Scribing

Once the machining allowance is validated, measurement data is automatically imported into the scribing system. After coordinate system alignment (transformation), the optimal scribing path is generated, and the system performs fully automated laser scribing on the workpiece. Image | Automated 3D Measurement, Allowance Analysis, and Scribing

Solution Advantages

Full Automation: Both measurement and scribing are fully automated. The entire cycle for a single casting takes only about 15 minutes, drastically increasing throughput.

Reduced Dependency on Manual Expertise: Precise, comprehensive allowance analysis eliminates reliance on operator experience, reducing material waste and scrap rates.

Data-Driven Support: Real-time data display and customized reporting provide solid empirical support for allowance determination and subsequent machining steps.

Environmentally Robust: Designed for complex industrial shop floors, the VISION3D solution overcomes space and environmental constraints, further enhancing inspection precision and efficiency.