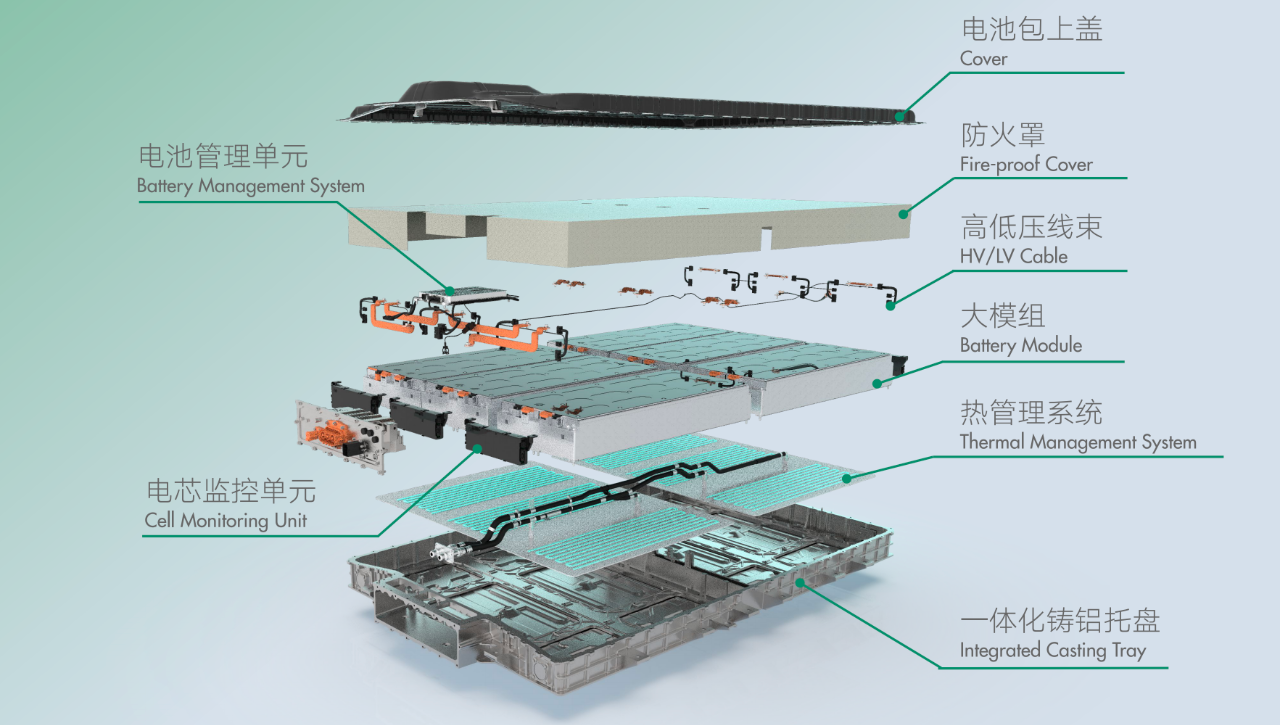

Automated 3D Metrology for NEV Battery Tray

As the primary structural component for Power Battery Packs in New Energy Vehicles (NEVs), the battery tray serves as a critical shield against external environmental impacts. It must meet exceptionally high standards for load-bearing capacity and assemblability. However, battery trays are susceptible to issues such as deformation and cracking during production. Therefore, implementing automated 3D inspection to ensure quality has become an indispensable part of the automotive manufacturing process.

Project Inspection Scope

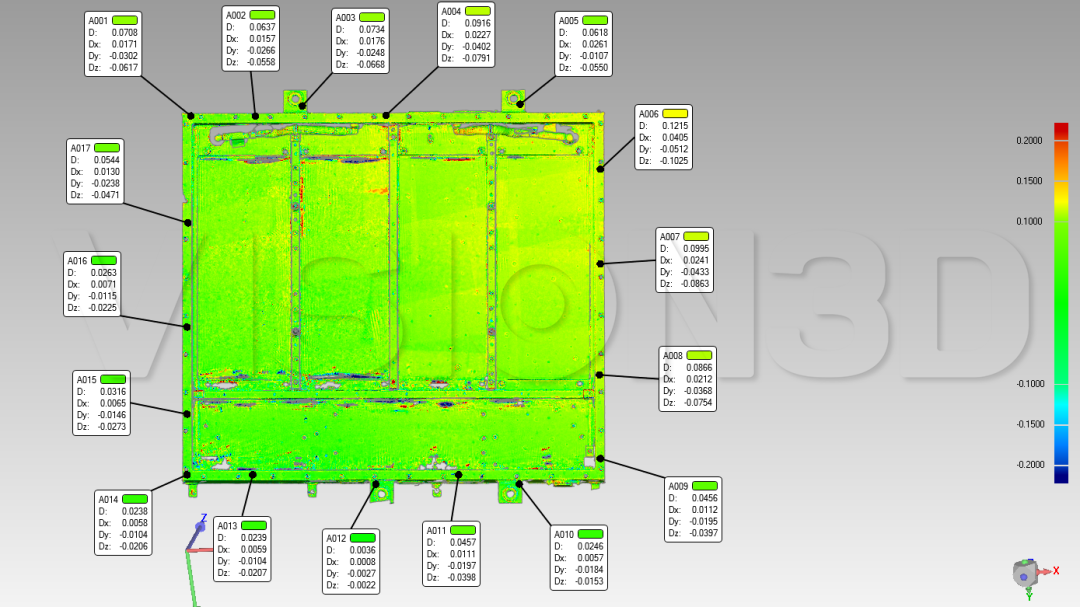

Surface Profile Deviation Measurement

Due to the large dimensions of the battery box and the stringent requirements for waterproofing and airtightness, 3D quality inspection of the surface profile and dimensions is essential to ensure sealing integrity, assembly quality, and the elimination of safety hazards.

Hole Feature Inspection

Battery trays contain a high density of through-holes, threaded holes, and smooth holes. Key dimensions, including hole positions and diameters, must be inspected to guarantee product quality.

VISION3D Automated Inspection Solution

The AutoScan Series Automated 3D Measurement System is deployed for the automated quality control of automotive battery trays. Equipped with a high-performance 3D sensor, the system rapidly captures intricate surface details and acquires comprehensive dimensional data. Furthermore, the system's wide robotic arm reach effectively addresses the challenges of large-scale inspection for battery trays and other medium-to-large components.

Automated Measurement & Rapid Acquisition of High-Precision Data

The AutoScan series enables target-free (markerless) automated measurement. Utilizing multi-view automatic registration technology, the system seamlessly merges measurement data to rapidly generate high-quality point clouds. With a single-frame acquisition time of less than 1 second and a total cycle time per part of approximately 180 seconds, it easily fulfills the demands of high-volume production inspection.

Optimized Algorithms for Precision on Reflective Surfaces and Hole Features

Leveraging a multi-exposure algorithm based on phase-weighting fusion and grayscale image-based hole extraction technology, the system achieves high-quality and efficient detection of hole features. It captures critical dimensions such as hole position, diameter, and center-to-center distance, achieving a hole position accuracy of ±0.1 mm.

Automated Generation of Customized Inspection Reports

The system automatically performs a CAD-to-Part comparison between the scanned data and the original nominal model to generate customized inspection reports. Based on batch measurement data, the software analyzes variation trends of key points and features, providing actionable insights to optimize manufacturing processes.