Quality Control for Automotive Piping Systems

Compared to traditional Internal Combustion Engine (ICE) vehicles, New Energy Vehicles (NEVs) demand higher integration and more precise thermal management. This imposes stricter requirements on the lightweighting and durability of piping assemblies. As the "circulatory system" of NEVs, any dimensional deviation in the piping can lead to critical safety hazards, such as coolant leakage or brake failure. Therefore, quality control for automotive piping is of paramount importance.

Workpiece: Automotive Cooling Oil Pipe

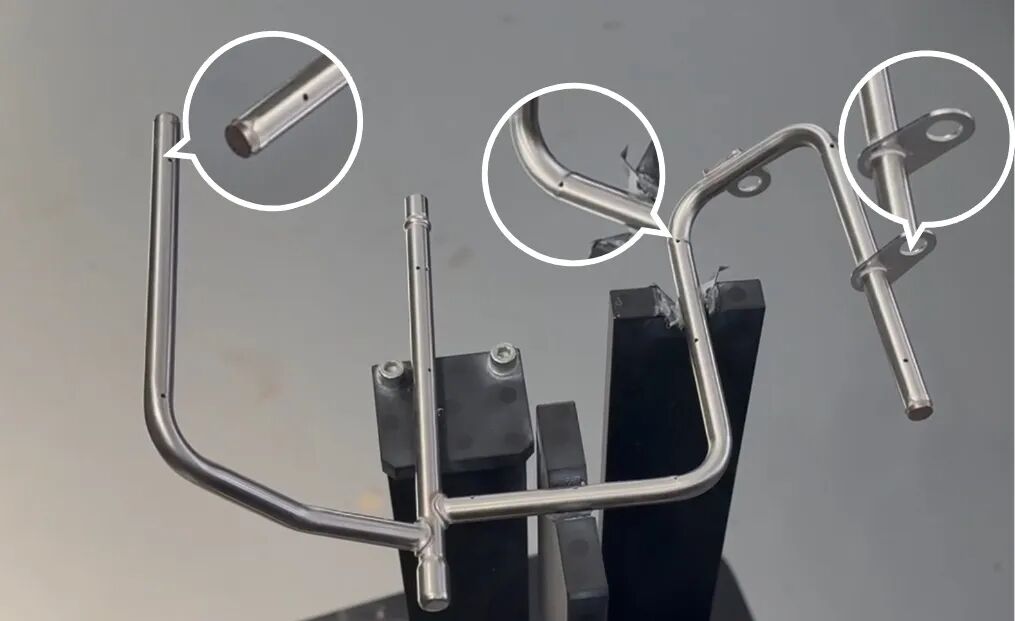

Measurement Challenges

- Complex Features: Inspection requirements involve intricate geometries, including cross-sectional distances, spatial angles, bracket aperture diameters, and position tolerances.

- Highly Reflective Surfaces: The smooth, glossy surface of the pipes often causes severe specular reflection, leading to overexposure and loss of point cloud data during scanning.

- Data Silos: Traditional gauge-based inspection relies on manual judgment and is limited to fixed key features. The lack of digital records prevents the establishment of quality traceability systems and process optimization.

Advantages of VISION3D Scanning Solution

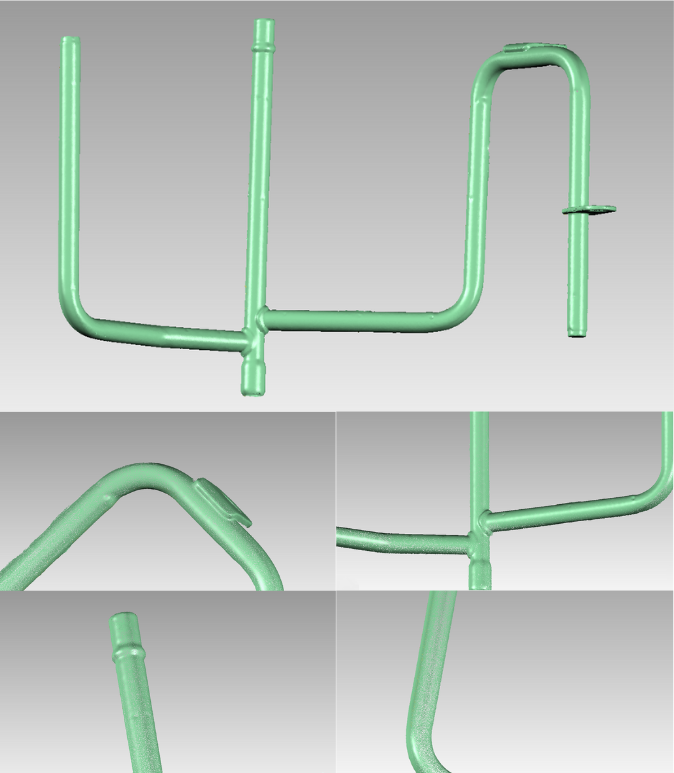

Rapid Generation of High-Quality Point Cloud Data

- Utilizes the PowerScan 5M Blue Light Area Scanning System, delivering a single-shot accuracy of 0.015 mm. It precisely captures features such as cross-sectional distances, spatial angles, bracket apertures, and position.

- Achieves high-speed scanning at 0.2s/frame, completing a full 360° point cloud acquisition of a single pipe within 30 seconds.

Automated Measurement with Flexible Operation

- Markerless Scanning: Eliminates the need for targets on the workpiece or fixtures, allowing for flexible loading and switching of parts.

- Intelligent Exposure Algorithms: Overcomes highly reflective surfaces without the need for developer spray. "Plug-and-play" scanning directly outputs complete point cloud data.

- AI-Driven Path Planning: Automatically recognizes the spatial trajectory of the pipe to plan scanning paths. This removes the need for physical gauges or manual tools, enabling fully automated measurement of complex structures like bent pipes and multi-branch manifolds.

Visualized Data Analysis & Digital Inspection Reports

-

Generates SPC (Statistical Process Control) trend charts for key features, providing an intuitive view of dimensional fluctuations.

-

Automatically compares data against CAD models to generate deviation color maps. The system produces digital inspection reports encompassing 3D deviation data and dimensional tolerances, supporting the creation of a traceable, full-lifecycle quality database.

Application Scenarios

This solution is widely applicable across various stages of automotive piping manufacturing:

- R&D and Design: High-fidelity reverse engineering for all types of piping.

- Prototyping & Validation: Confirmation and adjustment of machining parameters.

- Quality Improvement: Continuous process optimization powered by historical measurement databases.

- Mass Production: Implementation of flexible inspection and fully automated 100% inline inspection.

The rapid evolution of New Energy Vehicles has set unprecedented standards for the precision and reliability of piping systems. The VISION3D Scanning & Measurement Solution provides a high-precision, fully automated, one-stop platform, empowering automotive piping quality control through advanced digitalization.