Dimensional Inspection of Automotive Sheet Metal Parts

In automotive manufacturing, sheet metal parts are critical components, accounting for 60% to 70% of a vehicle's total composition. Their dimensional accuracy directly dictates the assembly quality of the entire vehicle. However, the production of sheet metal involves complex processes—including stamping, hemming, and bending—which make parts highly susceptible to surface irregularities, deformation, and cracking.

Inspection Challenges for Sheet Metal Parts

- Workpiece Characteristics: Sheet metal parts often have irregular shapes and low rigidity, making them prone to deformation during positioning, supporting, and clamping. This poses significant difficulties for pre-inspection setup.

- Complex Hole Features: Parts feature an extensive array of mounting holes, such as threaded holes, slotted holes, and irregular apertures. Their complex geometries and spatial distributions increase inspection difficulty.

- Surface Reflectivity: Highly reflective areas on sheet metal surfaces interfere with optical measurement signals, leading to data inaccuracies and compromising the reliability of results.

- High Feature Density: A complex sheet metal part can contain dozens or even hundreds of hole features. Combined with other inspection items, traditional methods fail to achieve the required efficiency.

Limitations of Traditional Methods: Conventional manual visual inspection and customized hard gauges rely heavily on human judgment and fixed hardware. These methods suffer from subjective bias, low efficiency, poor traceability, and an inability to adapt to rapid process changes, failing to meet the high-precision and high-efficiency demands of modern automotive manufacturing.

VISION3D Automated Inspection Solution

Exceptional Feature Capture Capability

With a measurement accuracy of up to 0.008 mm, integrated with advanced point cloud denoising and sampling algorithms, the system clearly captures fine features such as threaded holes and studs. In complex engine compartment inspections, it precisely acquires dimensional and positional data for micro-studs.

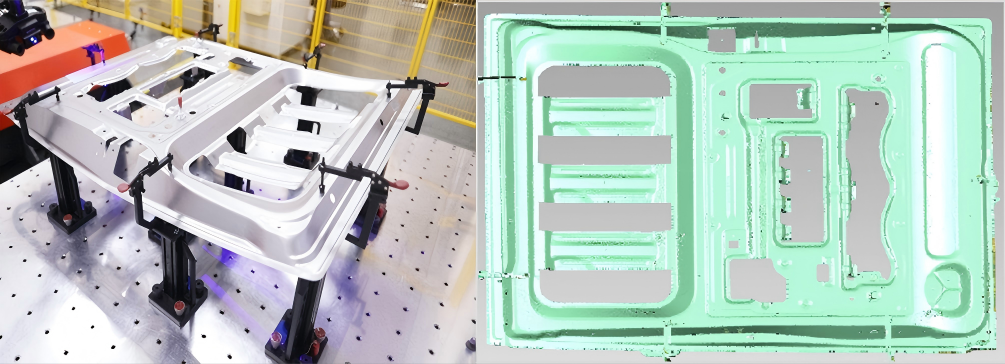

Robust Data Registration (Stitching)

Our unique Target-free (Markerless) Registration technology provides flexible data merging capabilities. Whether for in-line production inspection or off-line batch sampling, the system completes tasks rapidly without tedious positioning or target-sticking, significantly boosting throughput.

Intelligent Handling of Reflective Surfaces

By utilizing intelligent exposure algorithms, high-quality point cloud data is acquired without the need for anti-glare sprays (sprinkling/powdering). This advantage is particularly prominent in exterior trim inspection, ensuring accuracy while preventing surface damage to the parts.

Guaranteed Operational Stability

Built-in intelligent thermal control ensures the sensor head maintains stable precision during prolonged use. Even in challenging shop floor environments with fluctuating temperatures, the equipment operates consistently to guarantee data accuracy and repeatability.

Precision Inspection Applications

Inspection of Slots, Studs, and Holes

For irregular, closely spaced, or reflective slots and studs, VISION3D employs non-contact blue light 3D measurement. Unrestricted by narrow spaces or deep recesses, the system collects data from multiple angles. Combined with proprietary point cloud algorithms, it delivers a clear representation of critical details.

Trim Line Inspection

To address the thin edges, high reflectivity, and irregular contours of sheet metal trim lines, the structured-light 3D sensor utilizes high-performance algorithms to precisely capture trim line dimensions. This allows for the timely detection of quality issues like uneven trimming, effectively preventing gaps or interferences during final assembly.

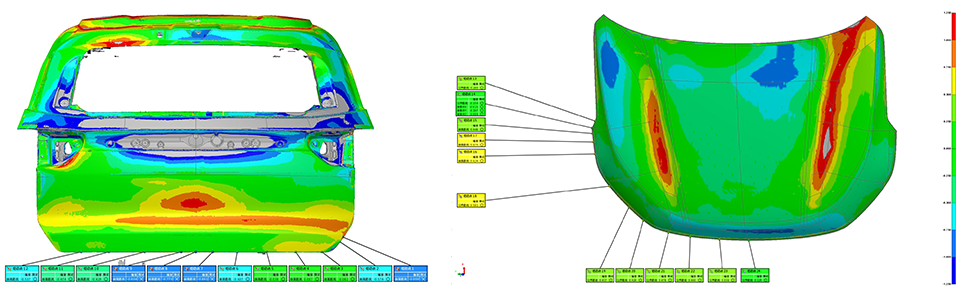

GD&T Inspection (Position, Parallelism, Flatness, etc.)

By aligning and comparing scanned data with the original CAD nominal model, the software intuitively displays deviations in hole positions, surfaces, and trim lines, as well as GD&T parameters. Furthermore, batch data analysis provides instant quality feedback and root-cause traceability, offering robust data support for process optimization.

Successful Project Applications

VISION3D has established a mature Automated Blue Light 3D Inspection Solution, successfully deployed at leading enterprises across the automotive supply chain, including SAIC-GM-Wuling (SGMW) and Anqing Changqing Auto Parts. The solution meets OEM requirements for full-dimensional inspection, statistical data analysis, digital reporting, and comprehensive cost control, empowering companies to strictly manage vehicle quality and enhance market competitiveness.