VISION3D Finishes Pre-A Series Funding of Nearly 100M RMB; RocketsCapital and Shunwei Capital Lead Investment, Xiaomi Corporation Increases Stake

Recently, Wuhan VISION3D successfully completed its Pre-A and Pre-A+ strategic financing rounds, totaling nearly 100 million RMB.

The funding was co-led by RocketsCapital (XPeng Motors Ecosystem Fund) and Shunwei Capital, with continued follow-on investment from existing shareholder Xiaomi Strategy Investment. Other market-based institutions, including Hangxin Chuangzhi and Industrial Securities Capital, also participated. This successful round underscores the industry's and capital market's recognition of VISION3D' leadership in optical dimensional metrology, validating the company's breakthroughs in technical innovation, market expansion, and high-growth potential

As a leading enterprise in the field, VISION3D has spent years building a comprehensive product ecosystem covering Automotive Manufacturing, Aerospace, and General Industry. The company has achieved full-scenario coverage with both "Automated" and "Handheld/Portable" solutions.

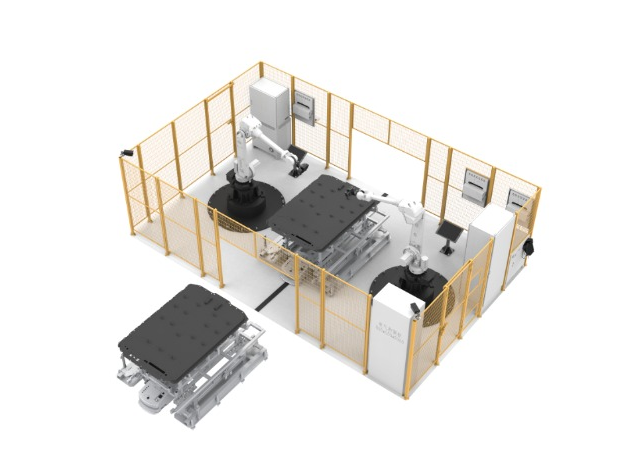

- EV Battery Inspection: VISION3D has achieved an industry-leading 149-second cycle time for in-line battery box measurement, covering over 600 critical dimensions. With a single-shot accuracy of 0.015mm, a measurement speed of 0.2s, and a tracker-free design, it overcomes challenges like structural complexity and occlusion, providing a "High-Precision + High-Efficiency" guarantee for quality control.

- Giga-Casting (Integrated Die-Casting) Inspection: VISION3D offers full-lifecycle coverage from process development to mass production monitoring. By modeling data in both thermal and cold states, it quantifies material shrinkage and deformation patterns, providing scientific data for mold compensation and shortening trial cycles. Its in-line system features real-time deformation tracking and SPC statistical analysis to improve casting precision.

- BIW (Body-in-White) Inspection: The solution enables high-speed, full-scale scanning of large panels such as side frames and closures (doors, hoods, and trunks). It captures critical features like gap and flush with high stability under harsh shop-floor conditions, ensuring dimensional consistency and building a robust defense for vehicle quality.

Focusing on lightweighting and structural safety, VISION3D has scaled applications in subframes and CCB (Cross Car Beam) inspection. For chassis components, high-speed in-line inspection analyzes welding deformation and assembly shifts, supporting NVH (Noise, Vibration, and Harshness) optimization.

In October 2025, VISION3D launched the VScan M Series metrological-grade handheld 3D scanners.

- Precision: 0.015mm

- Field of View (FOV): 520mm × 450mm

- Scan Rate: 60 FPS

This series bridges the gap between "automated in-line inspection" and "flexible on-site scanning." When paired with the self-developed VisionInspect 3D software platform, it enables seamless synergy across the entire hardware lineup.

Future Outlook

The funds raised will be used for R&D iterations of core technologies, expansion of product lines, and the perfection of global market channels. VISION3D aims to leverage this strategic support to deepen collaboration with ecological partners and inject more "Chinese Power" into the global intelligent manufacturing industry.