VISION3D Supports Smart Manufacturing for Xiaomi YU7 with Automated Blue-Light Metrology

On June 26, Xiaomi officially launched its first luxury high-performance SUV, Xiaomi YU7. During the launch event, Xiaomi highlighted key safety innovations—such as an “armored cage” steel-aluminum hybrid body structure and 2200 MPa ultra-high-strength steel—setting a new benchmark for vehicle safety. Behind every headline number is a manufacturing reality: safety commitments are ultimately delivered through uncompromising quality control and precise inspection.

As a provider of automated blue-light 3D scanning and measurement solutions, VISION3D participated in production inspection for Xiaomi YU7, supporting quality verification throughout key manufacturing steps.

A Targeted Inspection Solution for Two Core Components:VISION3D delivered a customized, efficient, and high-precision inspection workflow for two critical areas of the Xiaomi YU7 program:

- Integrated die-cast rear floor (post-casting)

- Battery tray

Inspection Challenges: Complex Features, Fast Takt Time, and Harsh Shop-Floor Conditions

Both components face demanding inspection requirements:

Battery tray (CTB architecture): measurement bottlenecks around complex features such as threaded holes and other detailed structures.

Die-cast rear floor: a newer integrated die-casting process with higher process variability; reflective machined holes; and fast line takt time—making it difficult for traditional inspection methods to balance speed and accuracy.

In practice, these translate into three major pain points:

- Complex surfaces and complex features are difficult to measure reliably

- Difficult to match inspection throughput with production takt time

- Online measurement is sensitive to environmental interference (temperature, vibration, ambient light, etc.)

Breaking the Bottlenecks with Non-Contact Blue-Light Metrology

VISION3D addressed these challenges with non-contact blue-light measurement technology, combining hardware innovation with a software ecosystem to form a fully automated, high-precision inspection loop.

- PowerScan Blue-Light Sensor Head

Using multi-view matching and adjustment optimization algorithms, plus CPU/GPU dual-engine acceleration, PowerScan helps reduce measurement interference from:reflective aluminum alloy surfaces、low-reflectivity/absorptive coatings (e.g., black electrophoretic paint).This improves point-cloud quality and measurement stability.

- VisionInspect Automated Measurement Software

VisionInspect supports both:marker-based stitching, and markerless intelligent stitching.Through feature matching and point-cloud alignment algorithms, it fuses multi-view scan data with high precision. Combined with ICP optimization and global constraint algorithms, the system can quickly generate high-accuracy point clouds for downstream analysis.

Key System Highlights

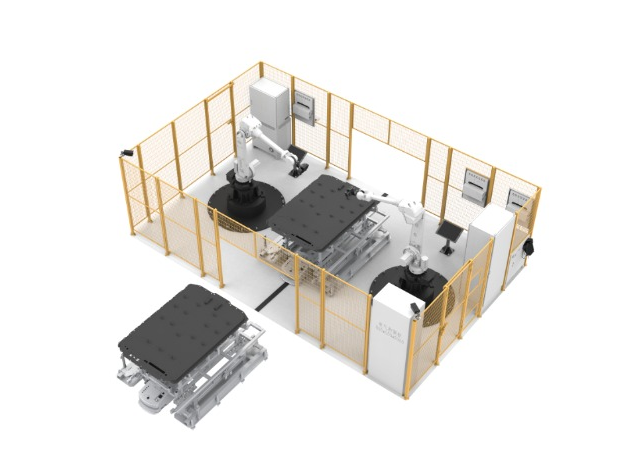

- Dual-Robot Collaborative Scanning for Full Coverage

Two robot arms equipped with PowerScan heads flexibly capture hard-to-reach regions such as deep cavities and bottom areas, helping minimize blind spots.Single-shot scan time: 0.2 s, supporting line takt time requirements.

- Fully Automated Measurement and Intelligent Full-Dimension Control

From loading to report generation, the workflow is designed for unattended operation:

automatic alignment to CAD,automated deviation analysis,automated report generation.Key dimensional deviations are visualized for fast decision-making.

- Robust Shielding Against Environmental Interference

A combination of:temperature-controlled room、light-blocking protection、anti-vibration foundation design.

Helps ensure stable measurement performance under complex shop-floor conditions.

End-to-End Delivery: From Requirements to On-Site Validation

Driven by in-house technology and scenario-based innovation, VISION3D supported the program across:

- requirement response

- equipment selection

- system integration

- software linkage

- measurement accuracy verification

- on-site protective engineering

these efforts help align manufacturing speed with quality assurance for Xiaomi YU7.