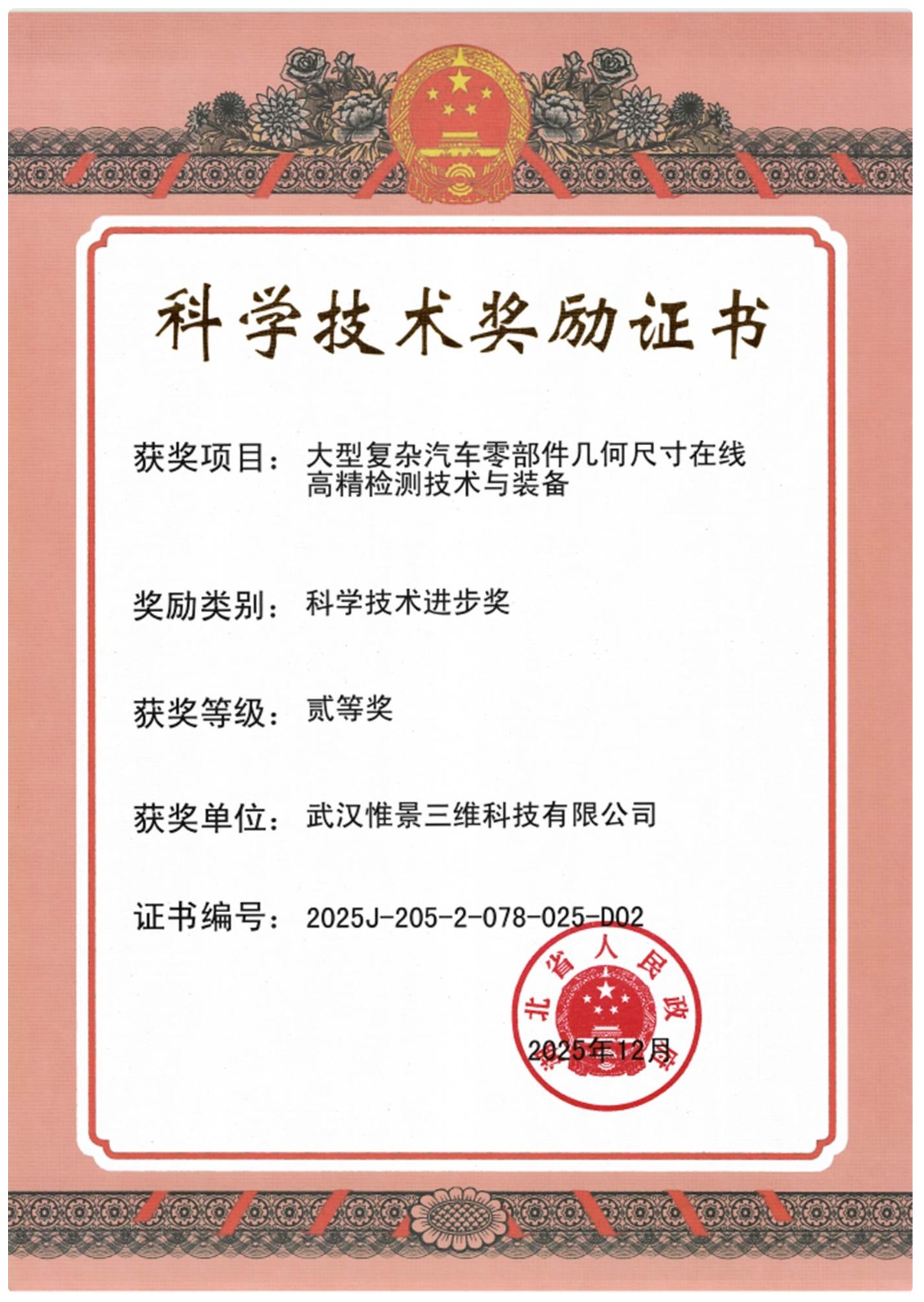

VISION3D Wins Hubei Provincial Science and Technology Progress Award as AutoScan Advances -Inline 3D Inspection for New Energy Vehicles

Wuhan, China -January 4, 2026 -At the Hubei

Provincial Conference on Science and Technology Innovation held at Hongshan Auditorium (Wuhan), the winners of the 2025 Hubei Provincial Science and

Technology Awards were announced. The project “Online High-Precision Geometric Measurement Technology and Equipment for Large and Complex Automotive Components”, jointly developed by Wuhan VISION3D Technology Co., Ltd.

(VISION3D) as a leading contributor together with Huazhong University of

Science and Technology and other universities and enterprises, received the

Second Prize of the Hubei Provincial Science and Technology Progress Award.

About the Hubei Provincial Science and Technology Awards

The Hubei Provincial Science and Technology Awards are provincial-level honors established by the People’s Government of Hubei Province to recognize individuals and organizations that have made outstanding contributions to scientific and technological innovation.

Addressing Inline Quality-Inspection Challenges in Automotive Manufacturing

As automotive manufacturing shifts toward electrification and higher integration, quality inspection for large, complex parts has become a practical bottleneck. Typical targets include battery packs and integrated die-cast body structures, where industry challenges are often described as incomplete coverage, insufficient accuracy, and insufficient speed.

To address these constraints, the project achieved key advances in:

- Reconstruction of highly reflective surfaces

- Intelligent multi-view planning

- Real-time processing of large-scale (up to billion-level) point

clouds

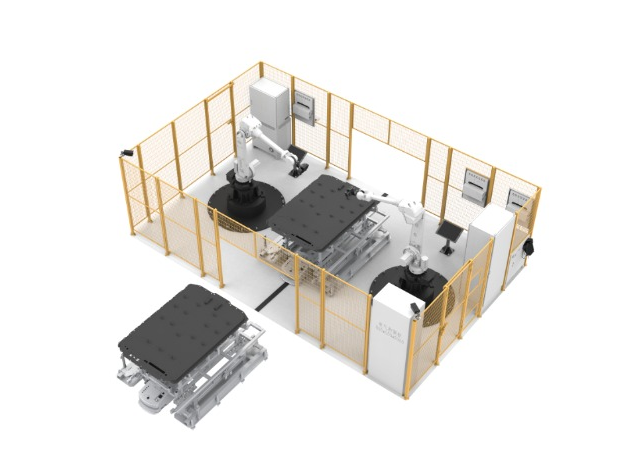

Based on these advances, VISION3D developed the AutoScan series of automated 3D measurement systems with independent intellectual property rights, enabling online high-precision inspection and supporting industrial deployment.

Three Core Technology Breakthroughs

With the rapid evolution toward electric vehicles and lightweight structures, manufacturing is changing quickly. For example, integrated die casting consolidates many parts into a single large component, increasing size and complexity while tightening requirements for dimensional control. After more than a decade of industry–university–research–application collaboration, the project established three core

capabilities:

High-precision acquisition for complex and reflective parts Large components often involve strong reflections and occlusions that can affect measurement stability. The project developed proprietary optical reconstruction and robust control techniques. The

resulting blue-light area-scanning 3D measurement system delivers:

- Single-measurement accuracy: ±0.01 mm

- Single-measurement time: < 0.2 s

- Designed for stable online operation in industrial environments

Intelligent path planning under multiple constraints and objectives

For high-mix, low-volume production, manual programming of measurement paths can be slow and inefficient. The project’s planning software supports:

- Viewpoint planning time: within 2 minutes

- Measurement coverage: > 97%

Efficient processing of large-scale unstructured point clouds Large measurement datasets create additional demands for registration, denoising, sampling, and dimension analysis. The project delivered key techniques including markerless multi-view registration, large-scale denoising and sampling, and efficient geometric dimension evaluation. The associated software reports:

Stitching accuracy: 0.01 mm + 0.02 mm/m

Analysis efficiency: 60% higher than mainstream international software

Industrial Deployment and Expanded Use Cases

According to the project information, the AutoScan series has been deployed across multiple sectors including new energy vehicles, power batteries, and commercial vehicles, and the technology has also expanded to aerospace manufacturing, supporting organizations such as Aviation Industry Corporation of China (AVIC) and China Aerospace Science and Technology Corporation (CASC) for R&D and production needs.

Looking Ahead

VISION3D will continue focusing on

industrial VISION3D inspection, guided by its mission to make industrial

inspection simpler and more efficient, and to further integrate advanced

measurement technologies with intelligent manufacturing scenarios.