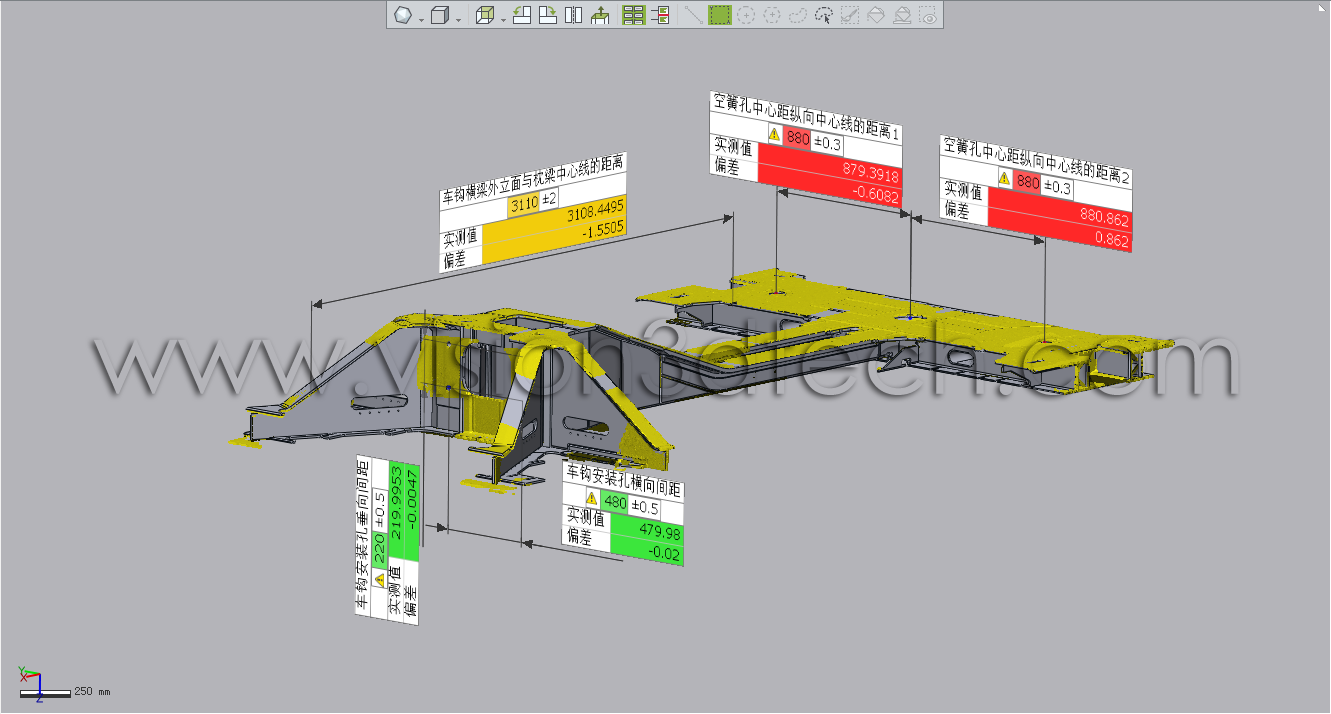

Automated 3D Measurement for Railway Draft Sill and Bolster Assemblies

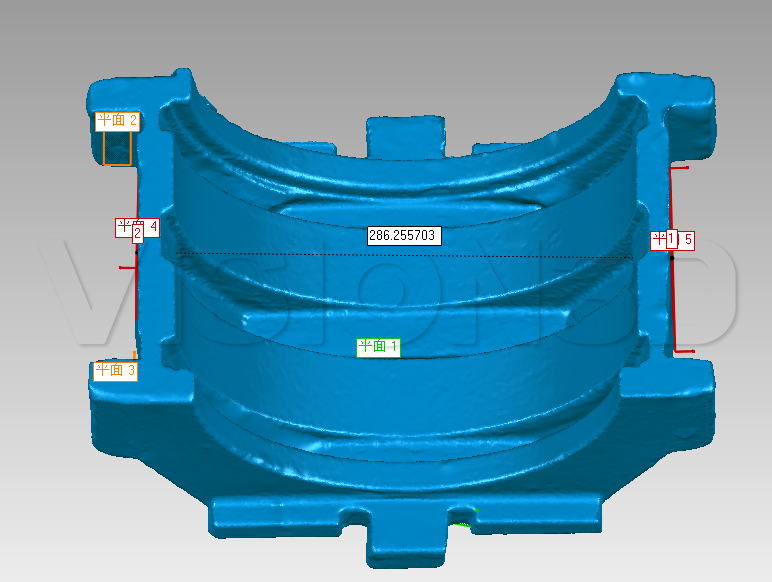

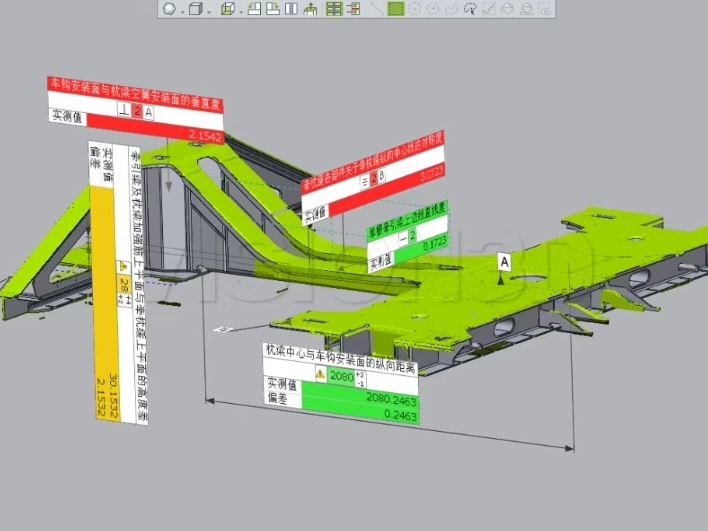

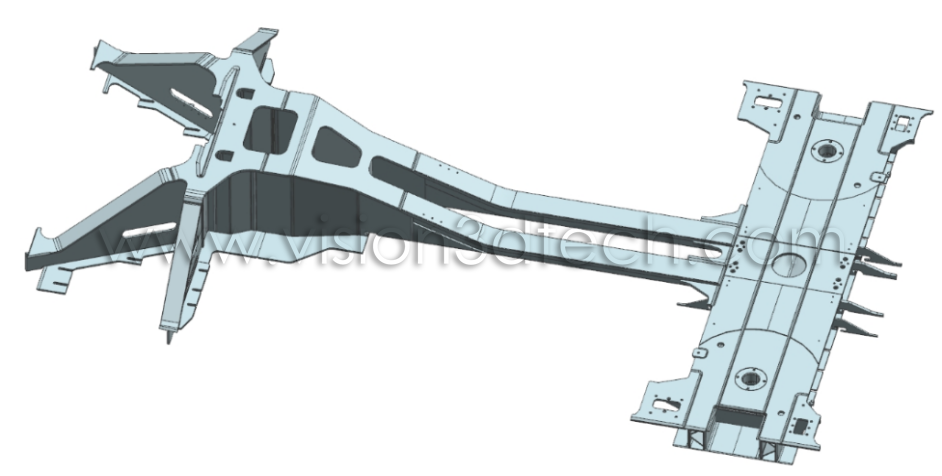

The draft sill and bolster assembly (known in the industry as "Qian-Zhen-Huan") is a critically stressed structural component of railway rolling stock with an extremely complex geometry. Structurally, it comprises the buffer beam assembly, bolster assembly, and draft sill assembly. Upon completion of manufacturing, more than 20 items—including dimensional accuracies and GD&T (Geometric Dimensioning and Tolerancing) parameters—must be inspected. Currently, manual inspection is the prevailing method, which suffers from low efficiency and poor precision.

Workpiece:

Railway Draft Sill and Bolster Assembly Dimensions: Approximately 4.0 m (L) × 2.6 m (W)

Technical Requirements:

- Inspection Cycle Time: ≤ 30 min

- Accuracy: ≤ 0.1 mm

Measurement Equipment:

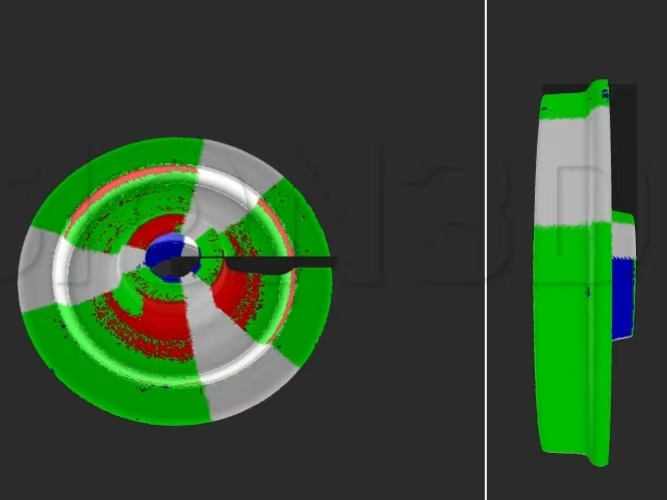

AutoScan™ 5000

Measurement Process:

The system executes fully automated measurements according to pre-planned paths, requiring no reference targets (markerless). Both data acquisition and data processing are performed automatically throughout the entire cycle.

Case Summary:

In this application, the AutoScan™ 5000 Measurement System integrates a high-performance scanning head, an industrial robot, a linear track (sliding rail), and a precision rotary table. The entire measurement process is completed within 28 minutes, with an overall measurement accuracy exceeding 0.1 mm.