Automated In-line Inspection System for High-Speed Rail Wheels at Elevated Temperatures

High-speed rail (HSR) wheels are globally recognized as high-tech products with extreme manufacturing difficulty. These wheels are produced through die forging and rolling, involving multiple stages such as sawing, forging/rolling, heat treatment, and precision machining. Such complex forming processes pose a significant challenge to the stability of automated production lines. A critical objective is how to improve the yield rate while achieving precise control over machining allowances.

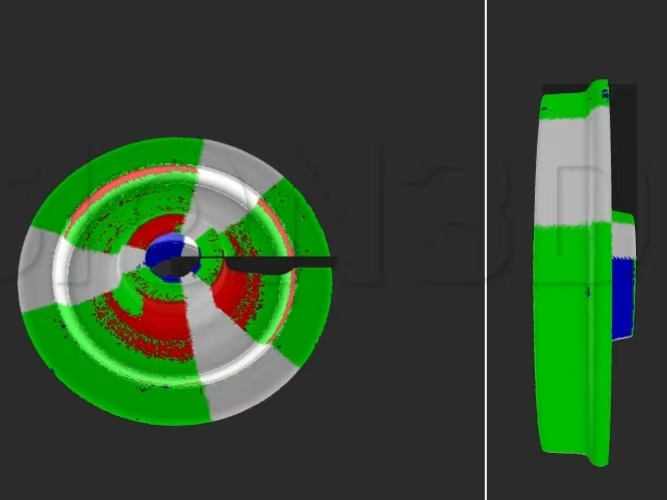

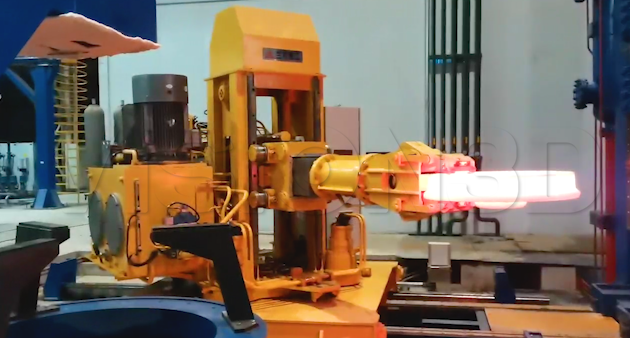

The HSR Wheel High-Temperature In-line Automated Inspection System, developed by VISION3D, performs automated 3D inspection on wheels in their red-hot state immediately following hot forging. This system promptly determines if a part meets the requirements for subsequent machining. Simultaneously, it allows for real-time adjustments of production line forming parameters based on measurement data, effectively reducing scrap rates and material waste.

High-Temperature Automated In-line Inspection

The wheel temperature is approximately 900°C. The entire process—including loading, unloading, and inspection—is fully automated with zero manual intervention. The inspection cycle time is as fast as 30 seconds per unit.

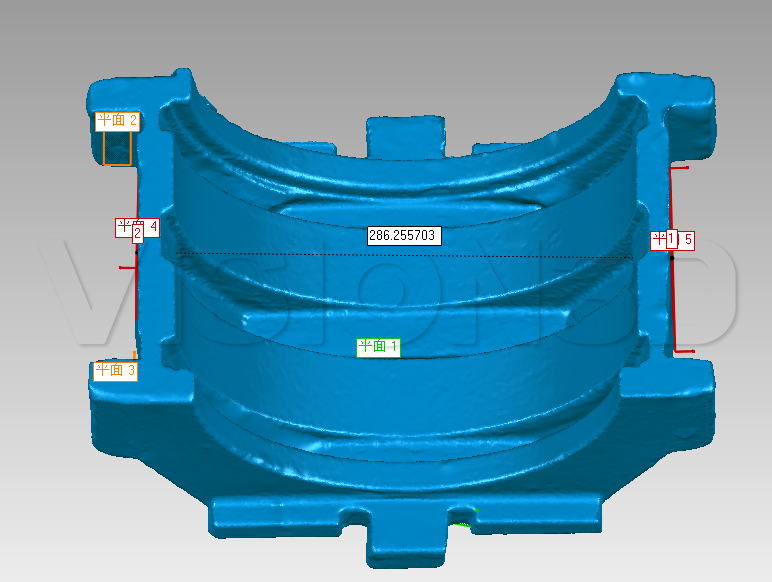

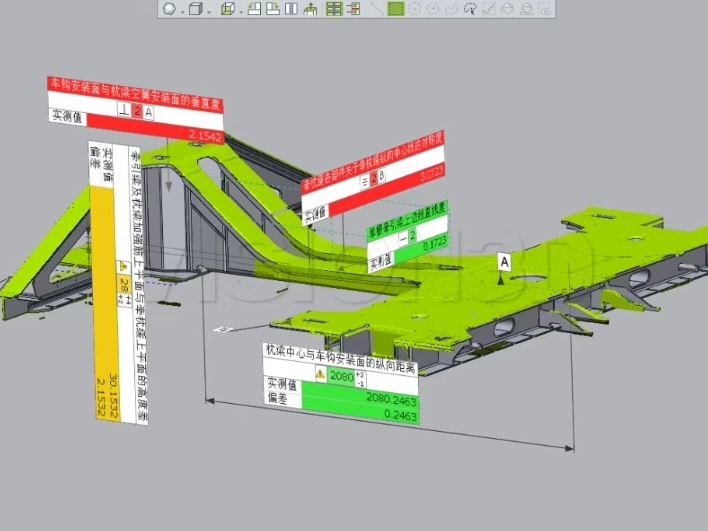

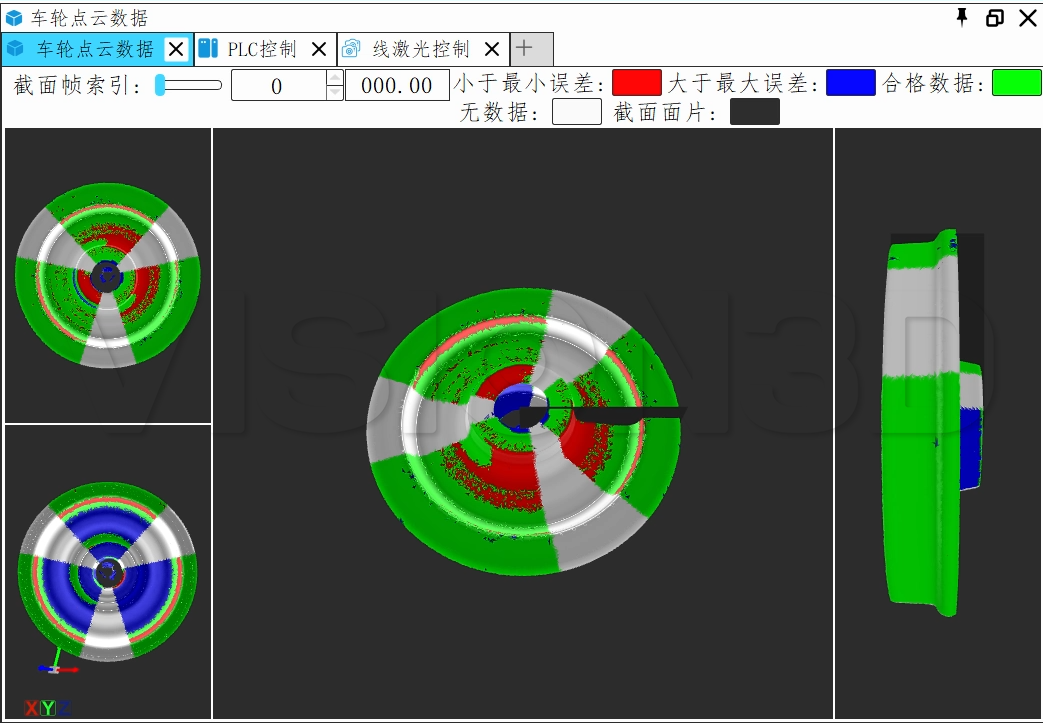

Specialized Precision Analysis Software

The software interface features three primary windows: the CAD-to-Part comparison view, the 2D cross-sectional data view, and the 2D sectional dimensional data view.

- Dynamic Mapping: The 3D and 2D images are fully synchronized; selecting any section in the 3D model immediately displays corresponding dimensional information in the 2D view.

- Data Efficiency: Each wheel can store 500 frames of high-precision sectional data. The files are highly optimized for a small footprint, allowing for offline review on any PC.

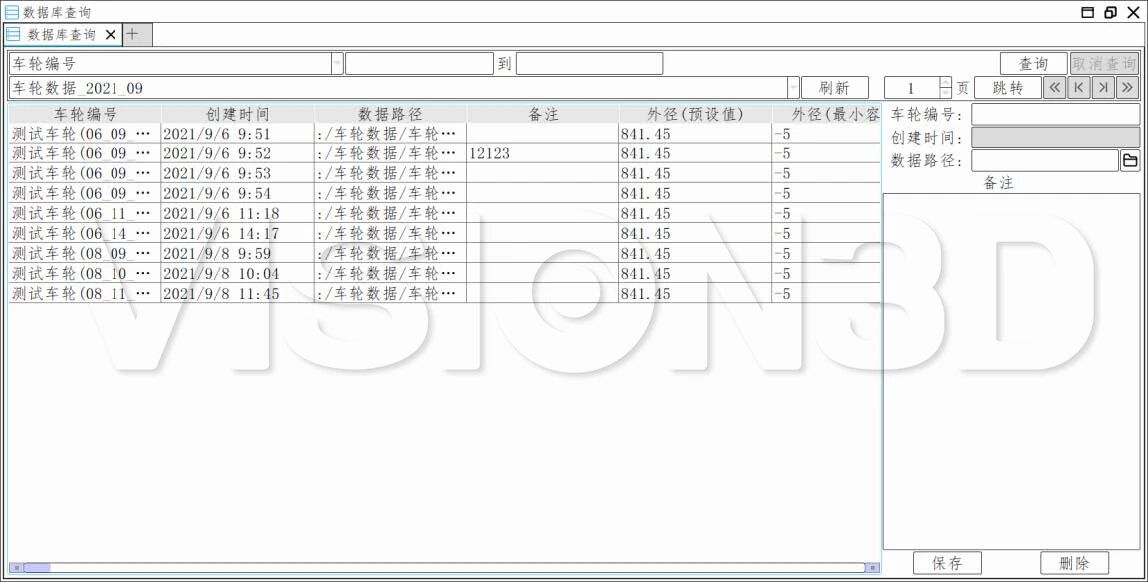

Process Optimization via Big Data

Scanned 3D data and inspection reports are automatically archived. Users can retrieve historical records based on wheel serial numbers or creation timestamps. By performing statistical analysis on dimensional accuracy across mass production batches, the system provides vital data-driven support for optimizing the die forging process.