Precision Inspection of Railway Bearing Saddles

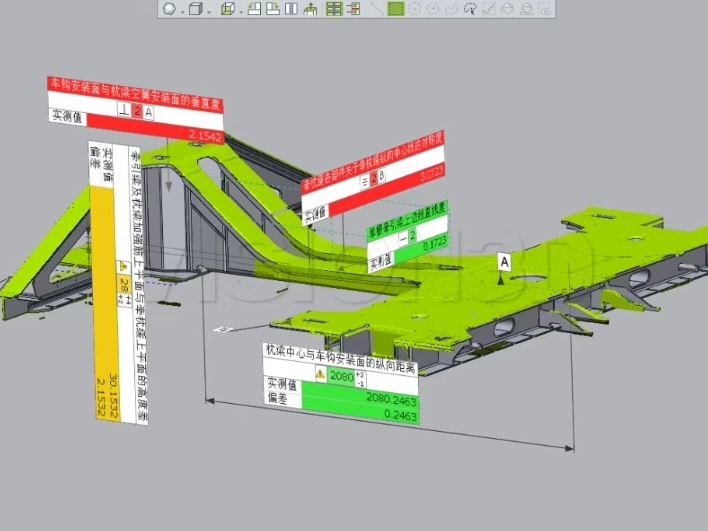

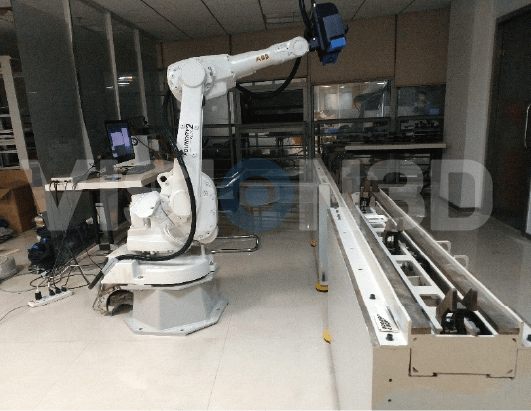

With the rapid advancement of high-speed rail, the trends toward higher speeds and heavier loads have imposed stricter requirements on operational safety. The manufacturing precision of critical components—including wheels, rails, and bearing saddles—dictates the safety and stability of train operations. Consequently, rigorous dimensional inspection is mandatory during both production and Maintenance, Repair, and Overhaul (MRO) processes. The AutoScan Series Automated 3D Measurement System, independently developed by VISION3D, has been deployed by numerous key entities in the rail transit industry, demonstrating long-term stability and exceptional performance.

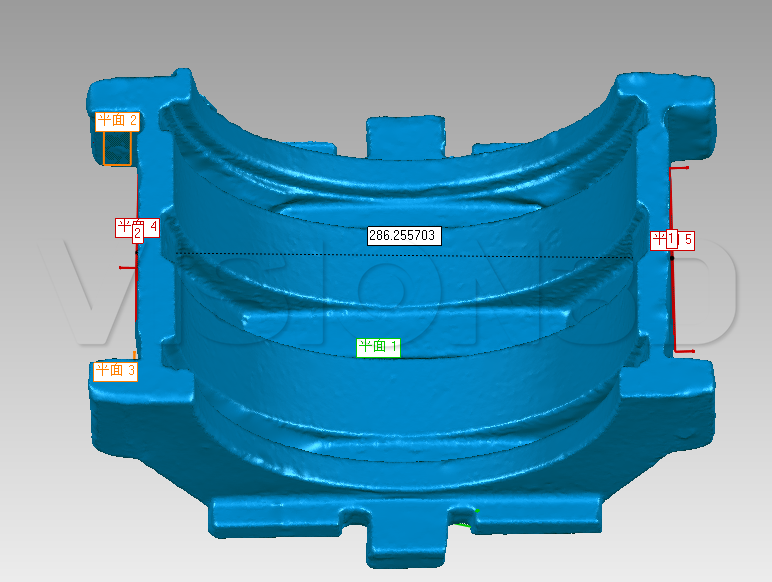

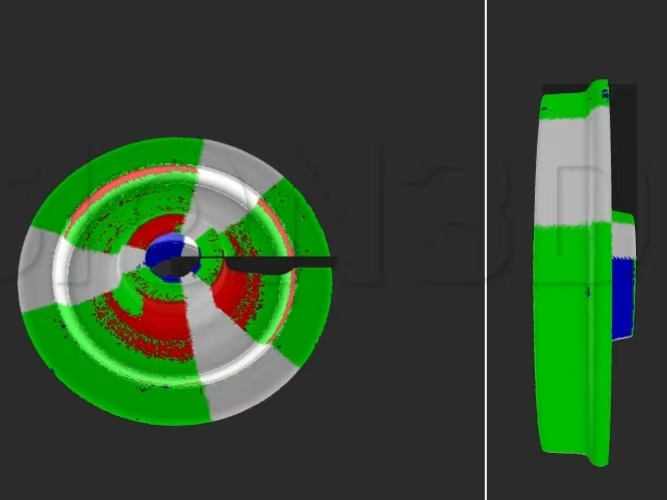

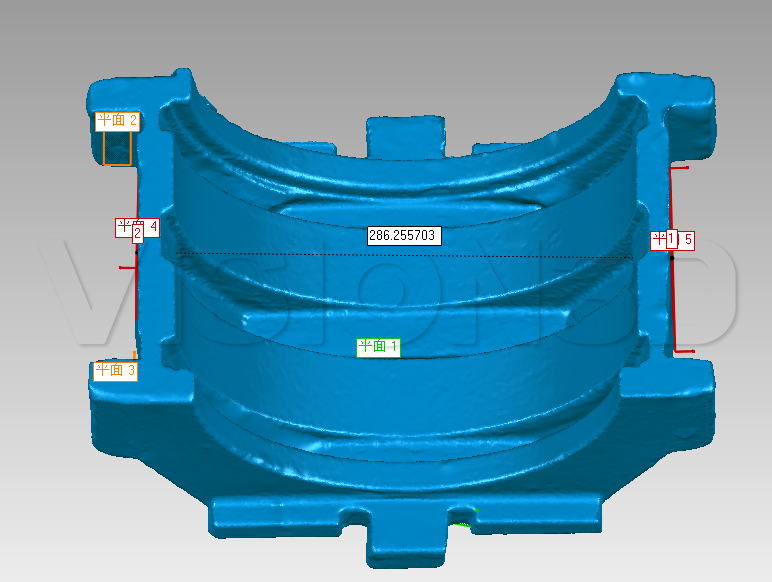

In the overhaul process at rolling stock depots, inspecting the wear of bearing saddle axle bushes using traditional methods is notoriously cumbersome and lacks sufficient precision. By implementing automated 3D scanning, the wear conditions of the axle bushes can be rapidly scanned and analyzed. The system automatically generates inspection reports and pass/fail signals throughout a fully unmanned process, significantly enhancing maintenance efficiency.

Measurement Equipment: AutoScan™ Series

Workpiece Status: Disassembled at ambient temperature during MRO

Part Dimensions: 250 × 160 × 147 mm

Cycle Time: 2 minutes per unit

Inspection Item: Saddle surface wear volume (wear depth)